Passenger Vehicles

Being FutuReady

How does Tata Motors ProLife remanufacture the engine?

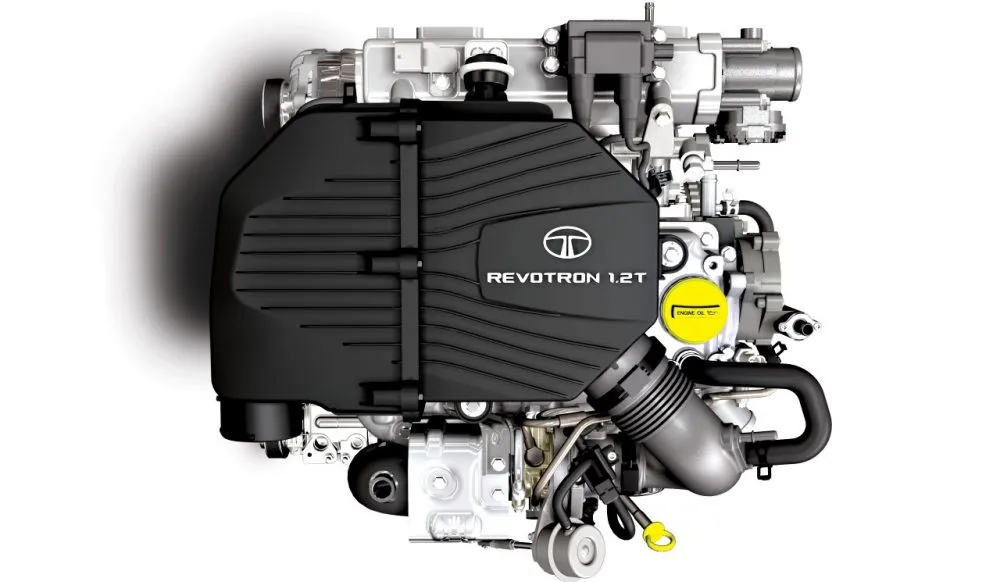

Tata Motors ProLife is an advanced engine remanufacturing solution that increases the performance of truck engines, clutch and pressure plates, truck cabins, by reducing downtime. The process involves a detailed set of steps, certified technicians and rigorous quality control measures.

In the event of an engine failure, customers usually seek the assistance of a mechanic who may opt to replace only the defective components. However, if an extensive overhaul is required, the engine might be disassembled in an environment prone to dust, and the mechanic may not always have the appropriate tools to rectify the engine properly. Consequently, during the engine reassembly, standard parts, including non-genuine, locally available parts of inferior quality may be utilised. This approach often leads to a short-term solution that may not necessarily be the optimal choice.

But at Tata Motors ProLife, the remanufacturing journey begins with carefully disassembling engines and all parts in the state-of-the-art facilities and dust free factory environment. This ensures that not only the faulty components are repaired but the whole engine is reconditioned.

Once disassembled, the selected components go through a thorough cleaning process to remove any contaminants. Advanced cleaning techniques ensure that the parts are free from dirt, debris, and previous engine residue. After cleaning, certified technicians restore the components to their original specifications using the right tools and advanced techniques.

The reconditioning phase also involves replacing worn-out or damaged parts with genuine Tata Motors components. This ensures the longevity and reliability of the remanufactured engine. All components go through rigorous testing, including advanced diagnostic procedures and quality control checks, to ensure optimal performance according to the standards of Tata Motors commercial vehicles.

Highly skilled technicians expertly reassemble the engine, following precise guidelines provided by Tata Motors. Each remanufactured engine undergoes a final inspection to ensure its functionality, reliability, and compliance. Finally, the engines are carefully packaged for shipment, ready to power Tata commercial vehicles across the country.

This offers several significant advantages. Truck cabins go hand in hand with engine performance. By remanufacturing engines, commercial vehicle owners can maximise the lifespan and utility of their vehicles.

By remanufacturing engines, Tata Motors not only remanufactures truck cabins but also contributes to a greener future. With the ProLife Engine, Tata Motors commercial vehicles lead the way in the automotive industry and can embrace prolongevity without compromising on quality or cost-effectiveness.

21 August, 2023

What is Tata Motors ProLife?

Tata Motors ProLife is an advanced engine remanufacturing solution that increases the performance of truck engines, clutch and pressure plates, truck cabins, by reducing downtime. The process involves a detailed set of steps, certified technicians and rigorous quality control measures.

In the event of an engine failure, customers usually seek the assistance of a mechanic who may opt to replace only the defective components. However, if an extensive overhaul is required, the engine might be disassembled in an environment prone to dust, and the mechanic may not always have the appropriate tools to rectify the engine properly. Consequently, during the engine reassembly, standard parts, including non-genuine, locally available parts of inferior quality may be utilised. This approach often leads to a short-term solution that may not necessarily be the optimal choice.

The process of remanufacturing the engine at Tata Motors ProLife:

But at Tata Motors ProLife, the remanufacturing journey begins with carefully disassembling engines and all parts in the state-of-the-art facilities and dust free factory environment. This ensures that not only the faulty components are repaired but the whole engine is reconditioned.

Once disassembled, the selected components go through a thorough cleaning process to remove any contaminants. Advanced cleaning techniques ensure that the parts are free from dirt, debris, and previous engine residue. After cleaning, certified technicians restore the components to their original specifications using the right tools and advanced techniques.

The reconditioning phase also involves replacing worn-out or damaged parts with genuine Tata Motors components. This ensures the longevity and reliability of the remanufactured engine. All components go through rigorous testing, including advanced diagnostic procedures and quality control checks, to ensure optimal performance according to the standards of Tata Motors commercial vehicles.

Highly skilled technicians expertly reassemble the engine, following precise guidelines provided by Tata Motors. Each remanufactured engine undergoes a final inspection to ensure its functionality, reliability, and compliance. Finally, the engines are carefully packaged for shipment, ready to power Tata commercial vehicles across the country.

This offers several significant advantages. Truck cabins go hand in hand with engine performance. By remanufacturing engines, commercial vehicle owners can maximise the lifespan and utility of their vehicles.

Conclusion:

By remanufacturing engines, Tata Motors not only remanufactures truck cabins but also contributes to a greener future. With the ProLife Engine, Tata Motors commercial vehicles lead the way in the automotive industry and can embrace prolongevity without compromising on quality or cost-effectiveness.